Helpful links: similar project, code we used.

During my fall semester I did an open option project to create a new motor control for a previous groups electric thread spinner. We didn’t quite land where we wanted to but were able to accomplish our main goals. We may go forward with this project in the future, but for now I need to emotionally recuperate from cannibalizing my wah pedal.

First we can take a look at the design of the pedal. It’s simple lever system with a geared 100kΩ potentiometer (potz) connected to a header on the circuit board. The power comes in from a battery or wall outlet 9V DC source. The 1/4″ jack gets connected in one side which goes through the board to the potz (which will vary the voltage as you move the pedal), which then goes back through the board and then to the output which will usually go to an amplifier.

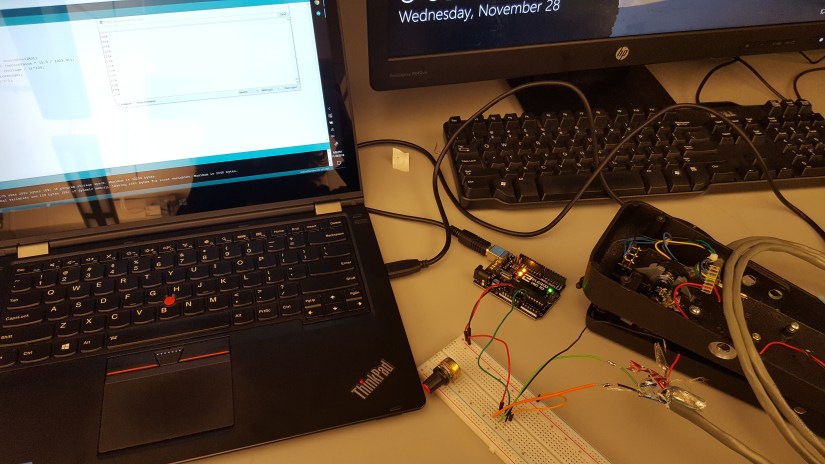

Now throwing out the mistakes and plan modifications of the story, this is what we actually did that was effective. First we took a different 10kΩ potz and attached it to a breadboard to test with an arduino (logic overkill, but easier for time constraints). After we saw that we could vary the speed outputs with the potz, I started modifying the wah pedal. After drilling a new hole and soldering new wires onto a subheader (to make it salvageable after the project), we tested with this setup.

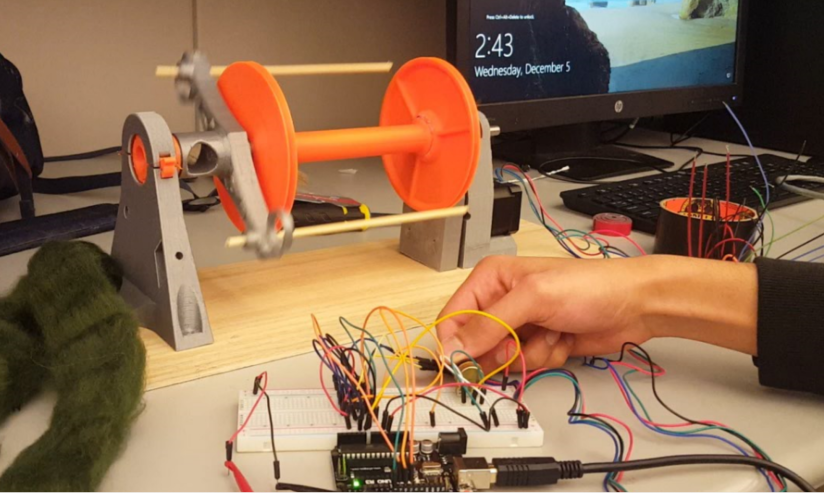

At this point we realized the 100k potz was too high (it would vary the voltage very smoothly but cut too much power to actually drive the motor), so we 3D printed some new gears and attached them to the 10k potz we used for initial testing. Once we were able to drive we setup our final circuit with an IC and out stepper motor.

We had primary success at this point and were able to make small improvements but ultimately not able to get to the top speed we were trying for. From our assessments, this is most likely due to gearing issues we encountered due to 3D printing a majority of the assembly. Regardless we were able to achieve a smooth speed curve and reduced the weight of the old design by half with a fully 3D printable assembly.